Fu Hsun Fiber Industries Presents FabGoalie AI Fabric Defect Detection System at Booth L1109 at TITAS 2025

Taipei City, Taiwan, October 14, 2025 – Fu Hsun Fiber Industries launches a prototype of FabGoalie AI, an AI-powered defect detection system developed in collaboration with National Yang Ming Chiao Tung University (NYCU) at booth L1109 at TITAS 2025.

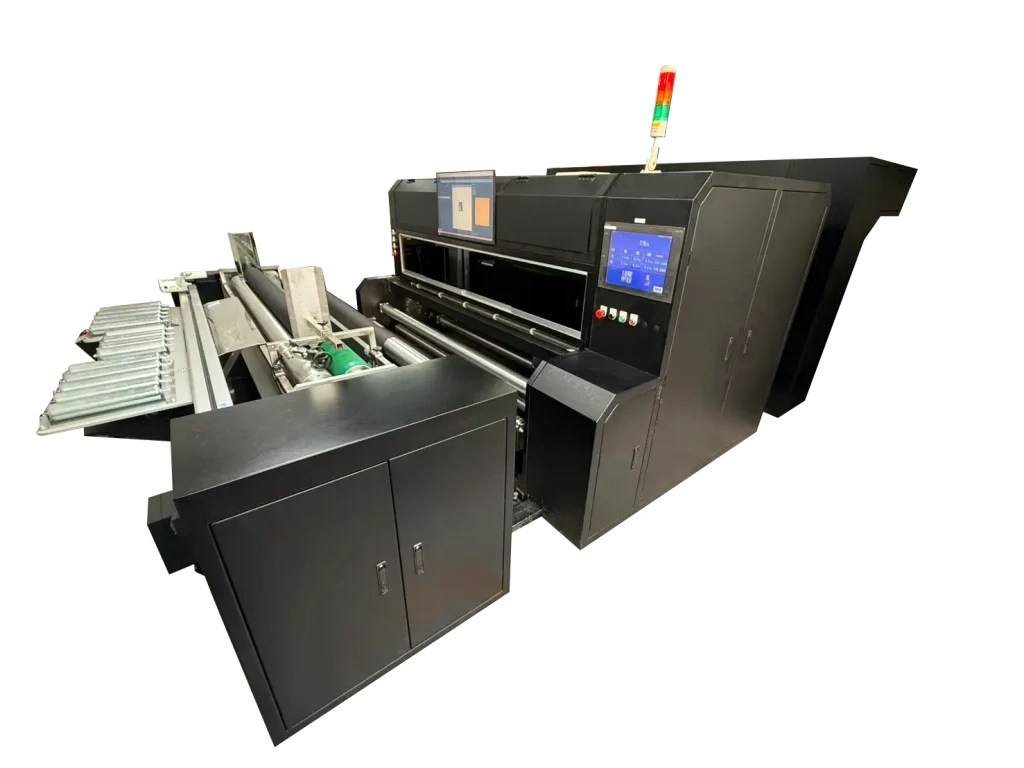

At the core of the system is an AI algorithm capable of detecting objects in fabric and classifying them into different defect categories. The integrated solution also features specialized hardware and a user-friendly graphical interface (GUI).

Fabgoalie AI detects over ten types of defects, including oil stains, dye stains, holes, broken yarn, snagging, and creases. The AI software is also capable of checking the color consistency and evaluates perceptual color differences across the left, center, and right sections of the fabric.

“The prototype is an important milestone for us. With FabGoalie AI, fabric producers can overcome the limitations of traditional manual inspection. I am glad that we have been able to push the boundaries once again,” said Tony Chen, Chairman and Board Member of Fu Hsun Fiber Industries. “Of course, there is even more potential ahead, and we look forward to feedback from the textile industry at TITAS.”

The system supports roll-to-roll inspection: Fabric moves from a cart directly to the winding station. By default, it uses seven cameras and an optical marking system to inspect fabrics at speeds of 25–30 meters per minute. The hardware is optimized for space efficiency, making it suitable for inline deployment in production environments.

Real-Time AI Detection Suited for the Fabric Industry

To meet the needs of production environments, the system’s GUI includes preconfigured tables and charts. The prototype features a dedicated display mounted directly on the machine, as well as a workstation for real-time monitoring within the production facility.

At the same time, the application is mobile-optimized and provides multiple reporting features. The GUI ensures a smooth user experience tailored to decision-makers in production environments. QR codes enable quick access to dashboards, while the multilingual web app supports accessibility from different locations and facilitates long-term analytics.

Fu Hsun Fiber Industries and NYCU are currently testing FabGoalie AI in real production environments. Together, they aim to deliver a solution that can be seamlessly integrated into modern fabric production facilities.

FabGoalie AI is not yet available for public sale; however, you can request a demonstration or inquire about its official launch.

About Fu Hsun Fiber Industries

Founded in 1963, Fu Hsun Fiber Industries has over 60 years of experience producing synthetic fabrics for some of the world’s leading sportswear brands. Specializing in high-performance polyester knits for functional applications, our commitment to continuous improvement enables us to deliver high-quality fabrics with short lead times.

Media Contact

Ferdinand Kunz

Marketing at Fu Fu Hsun Fiber Industries

Ferdinand@fuhsun.com

All rights reserved. All trademarks are the property of their respective owners.

Leave a Reply