FabGoalie AI Revolutionizes Fabric Production with Artificial Intelligence

FabGoalie AI is an AI-powered defect detection system specifically designed for the fabric industry. It offers a turnkey-ready solution that can be seamlessly integrated into modern fabric production facilities. On this page, you will find an overview of how the AI works, along with detailed information about the technical components of FabGoalieAI.

The Four Principles of FabGoalie AI

At the core of FabGoalie AI is an advanced AI software algorithm designed to detect and classify various types of fabric defects. The system operates based on four key principles: Deep Learning Technology, Automated Inspection and Seamless Integration, Diverse Defect Recognition, Smart Adaptation and Customization.

Deep Learning Technology

Leveraging deep learning technologies and neural networks, the development team trained the software on a large dataset of fabric images. This enables the detection of diverse defects. Today, FabGoalie AI is capable of overcoming the limitations of manual inspection. Moreover, it significantly improves both accuracy and efficiency.

Automated Inspection and Seamless Integration

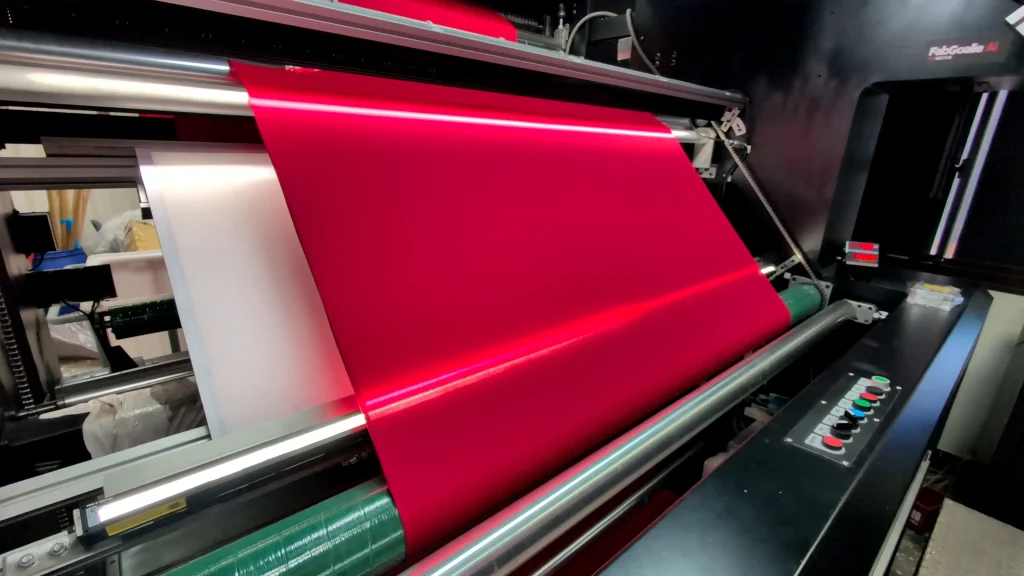

FabGoalie AI was never intended as a purely academic research project. In fact, from the ground up, the developers aimed for real-world application, including extensive field testing. Thus, the system is capable of continuous, real-time fabric inspection in production environments. It comes as a turnkey-ready solution. Fabric producers can deploy it seamlessly during the final quality control phase of fabric production.

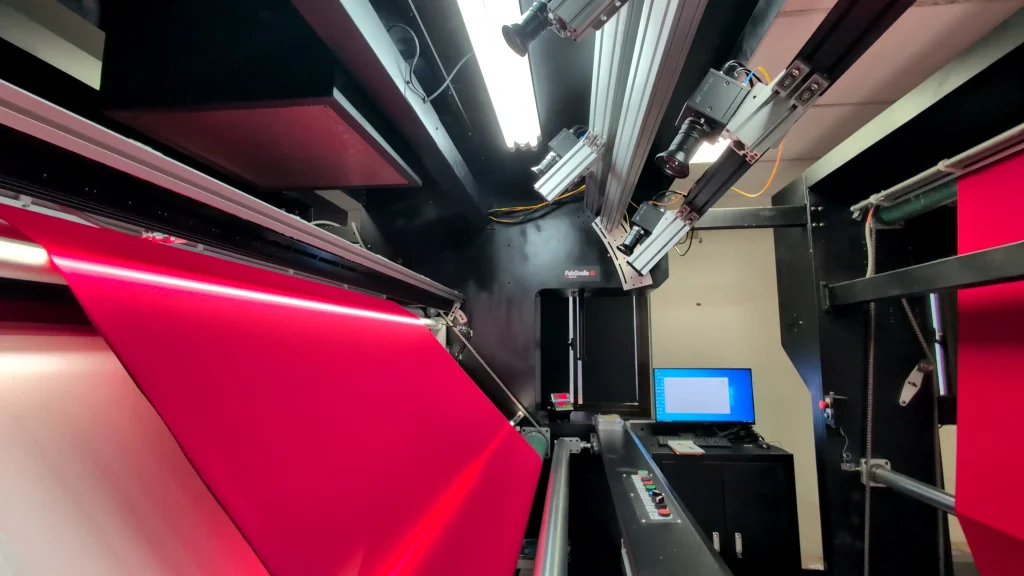

The hardware includes a servo control system, tension control, and a dedicated workstation. In addition, your team designed components to meet the demands of modern manufacturing environments.

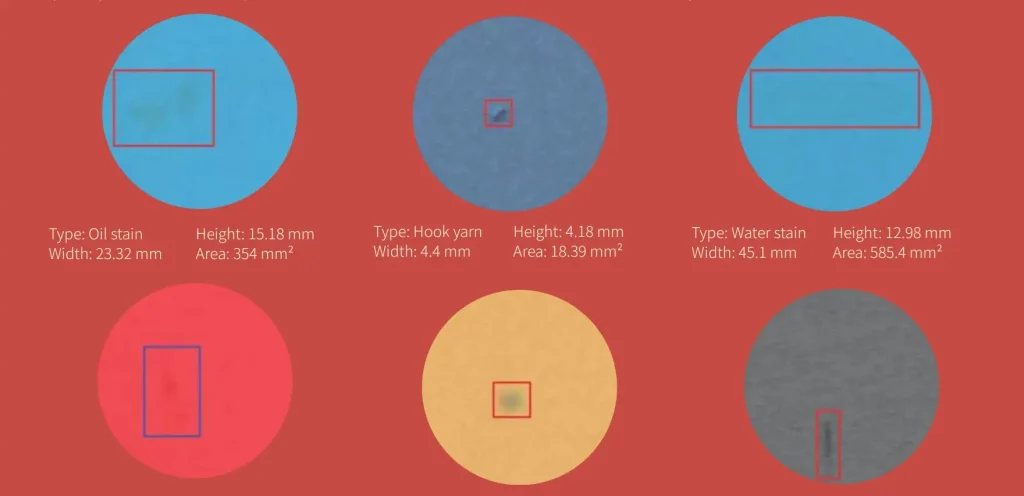

Diverse Defect Recognition

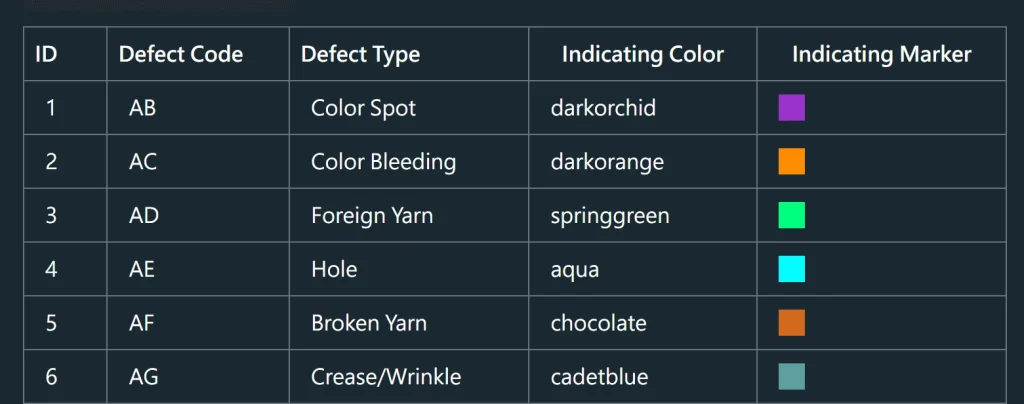

The system detects a wide range of common fabric defects, including oil stains, color stains, false yarns, holes, broken or hooked yarns, and wrinkles. As development continues, the system supports an expanding set of defect types. For example, the team added a new feature to detect color variations across different sections of fabric.

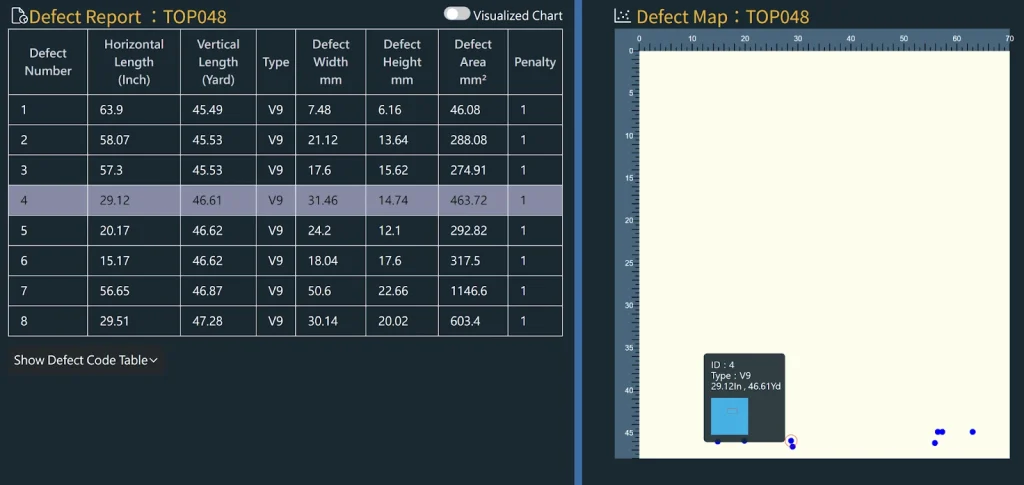

Moreover, FabGoalie AI also assigns a customizable “penalty score” to quantify the severity of each flaw. Based on this score, fabric producers can take targeted corrective actions, such as removing defective sections. The users can adjust these scores to align with specific quality standards.

Smart Adaptation and Customization

FabGoalie AI is an adaptive system with a modular design. Its one-stage detection approach supports real-time performance while allowing for future adjustments. With continuous data input, the system evolves and self-optimizes over time. This will improve detection accuracy, efficiency, and responsiveness to specific production needs even further.

Technical Components of FabGoalie AI

FabGoalie AI is more than just a piece of software. It is a fully integrated system that includes the AI algorithm, specialized hardware, and a user-friendly system interface with practical reporting features. We field-tested all components . Furthermore, the modular architecture allows easy maintenance, upgrades, and flexible configurations.

The AI Software Algorithm

At the core of the system lies an AI software algorithm built to detect objects in fabric and classify them into specific defect types. The engineers adopted a one-stage detection approach optimized for real-time performance.

In addition, the team at NYCU trained the AI to handle a wide range of fabric types and colors. Through a sophisticated machine learning process, the software supports diverse fabric structures, yarns, and materials.

FabGoalie AI delivers higher detection accuracy than traditional manual inspections. On top, it offers a more precise and consistent solution for flaw identification. These results are possible by advanced AI models and a deeper understanding of neural network behavior. The software architecture is able to perform well even with relatively small datasets and limited computing resources.

The Hardware Base of FabGoalie AI

The system’s most essential hardware components are high-resolution 8K industrial cameras to inspect the fabric. In addition, the system includes a servo control unit, tension control mechanisms, and a workstation. All of these parts support offline operation and compliance with common industry standards in the fabric industry.

Thanks to its modular design, user can add hardware components or upgrade after initial deployment. This flexibility is especially valuable when you evaluate investments in optical hardware. For example, while the first prototype used two cameras, the latest deployments feature up to four cameras. More cameras increase detection speed and accuracy, however, they also raise system cost. The optimal optical configuration depends on the specific use case and production environment.

The detection process begins with image acquisition via industrial-grade cameras paired with an optical marking system. FabGoalie AI converts these to grayscale and splits them into 128 smaller segments. Each segment has a resolution of 512×512 pixels, and the AI will analyze each individually. This preprocessing enables inspection speeds of up to 54 meters (approximately 60 yards) per minute. Besides this pace, it also allows the system to operate entirely on-premises with minimal computing and power requirements.

System Interface and Reporting

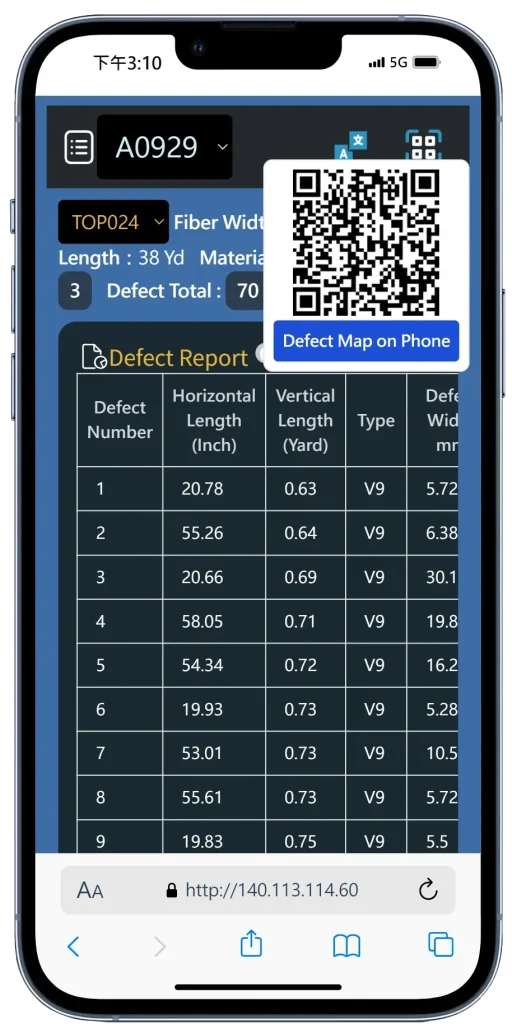

To support practical use in production environments, FabGoalie AI includes a graphical user interface (GUI) to ensure accessibility and ease of use. The user can access the interface from multiple locations. Moreober, it features preconfigured tables and a variety of charts to support clear and efficient data interpretation.

The application is mobile-optimized and offers several reporting features. It delivers a smooth and intuitive user experience, especially for production managers and decision-makers.

On top, the system allows seamless transitions between devices. It supports multiple languages by default, including Chinese, English, and Vietnamese. Specific graphs and reports can be accessed in the field simply by scanning a QR code. Users get full access without requiring any IT expertise.

Want More Details?

Download the datasheet for full technical specifications. If you have any questions, feel free to reach out. We are happy to answer your questions.